What is the steel pipe?

The steel pipe is a steel with a hollow cross section whose length is much larger than its diameter or

perimeter. As an important part of steel products, steel pipes are divided into seamless steel pipes and welded

steel pipes according to the production process.

1. Seamless steel pipe

Seamless pipe is a long strip of steel with a hollow cross section and no seams on the periphery.Seamless steel pipes are mainly used for petroleum geological drilling pipes, cracking pipes for petrochemicals, boiler tubes, bearing tubes, and high-precision structural steel pipes for automobiles, tractors, and aviation.

Due to their different manufacturing processes, they are divided into two types: hot-rolled seamless steel pipe and cold-drawn seamless steel pipe.

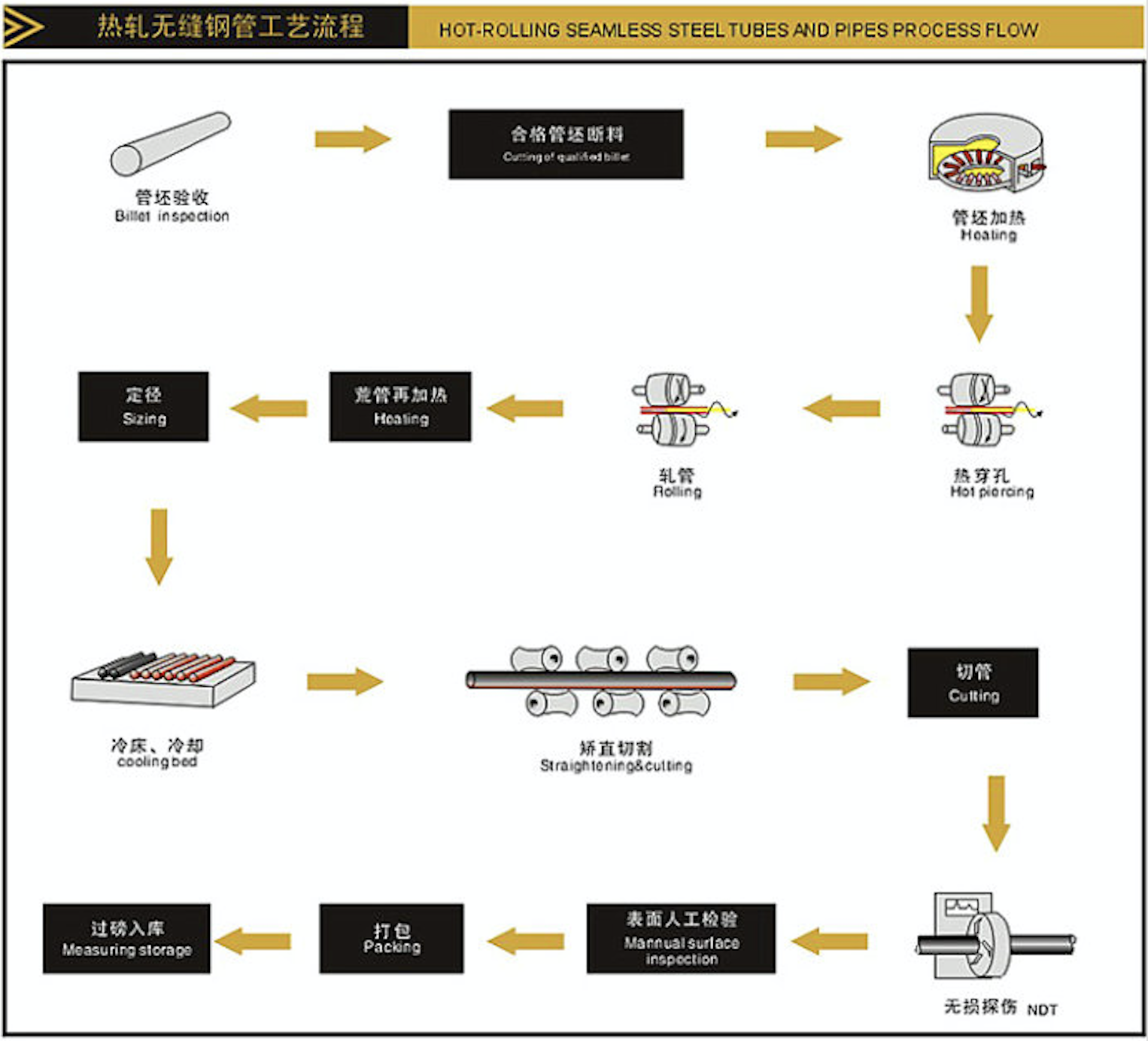

( 1 ) Hot-Rolled Seamless Steel Pipe Production Process:

The delivery state of hot-rolled seamless steel pipe is generally the hot-rolled state, which is delivered after heat treatment. Hot rolled seamless steel pipe is subject to strict manual selection by the staff after quality inspection, and the surface is oiled after quality inspection, followed by multiple cold drawing experiments, and perforation experiments after hot rolling treatment. If the diameter of the perforation is too large, straightening correction is required. After straightening, it is transferred to the flaw detector by the conveying device for flaw detection experiments. Finally, the labels are labeled and the specifications are arranged and placed in the warehouse.

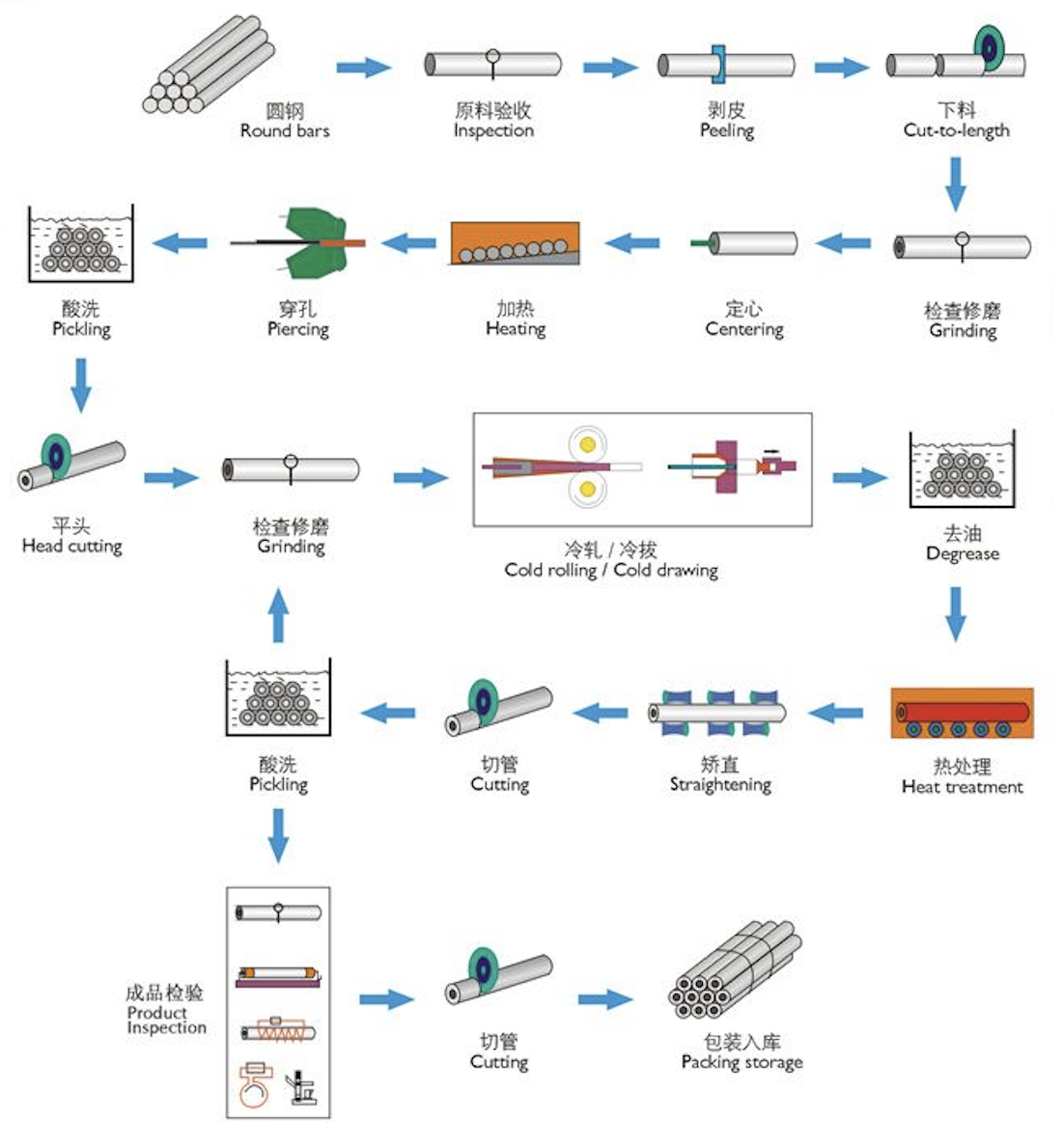

( 2 ) Cold-Drawn Seamless Steel Pipe Production Process:

The production process of cold-rolled seamless steel pipe is generally more complicated than hot-rolled. The appearance of cold-rolled seamless steel pipe is shorter than that of hot-rolled seamless steel pipe. The thickness of cold-rolled seamless steel pipe is generally smaller than that of hot-rolled seamless steel pipe. The surface looks brighter, without much roughness, and the ends don't have too much burr.

2. Welded Steel Pipe

It is a steel pipe made of steel plate or strip steel after being crimped and welded. Welded steel pipe is divided into Straight Seam Welded Steel Pipe and Spiral Welded Steel Pipe according to the form of weld.

(1)Straight Seam Welded Steel Pipe can divide into Electric Resistance Welding Steel Pipe and Longgitude Submerged Arc Welding Steel Pipe:

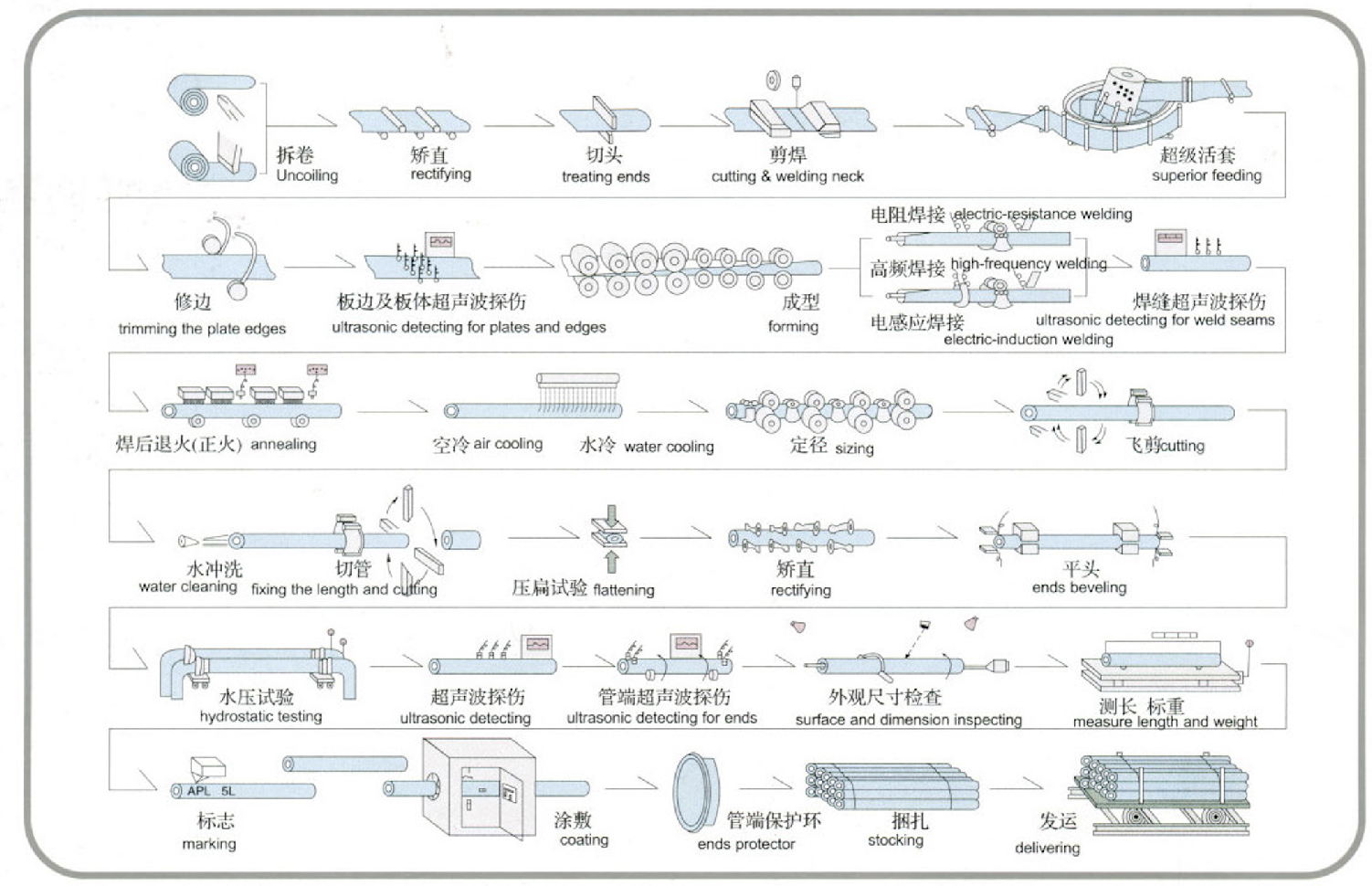

( 1.1 ) Electric Resistance Welding Steel Pipe Production Process:

The surface quenching and tempering heat treatment of ERW welded pipes is usually performed by induction heating or flame heating. The main technical parameters are surface hardness, local hardness and effective hardened layer depth. The surface quality of the steel pipe should be smooth, and no defects such as folding, cracking, delamination and overlap welding are allowed. Mainly used in water engineering, petrochemical industry, chemical industry, power industry, agricultural irrigation, urban construction and other fields.

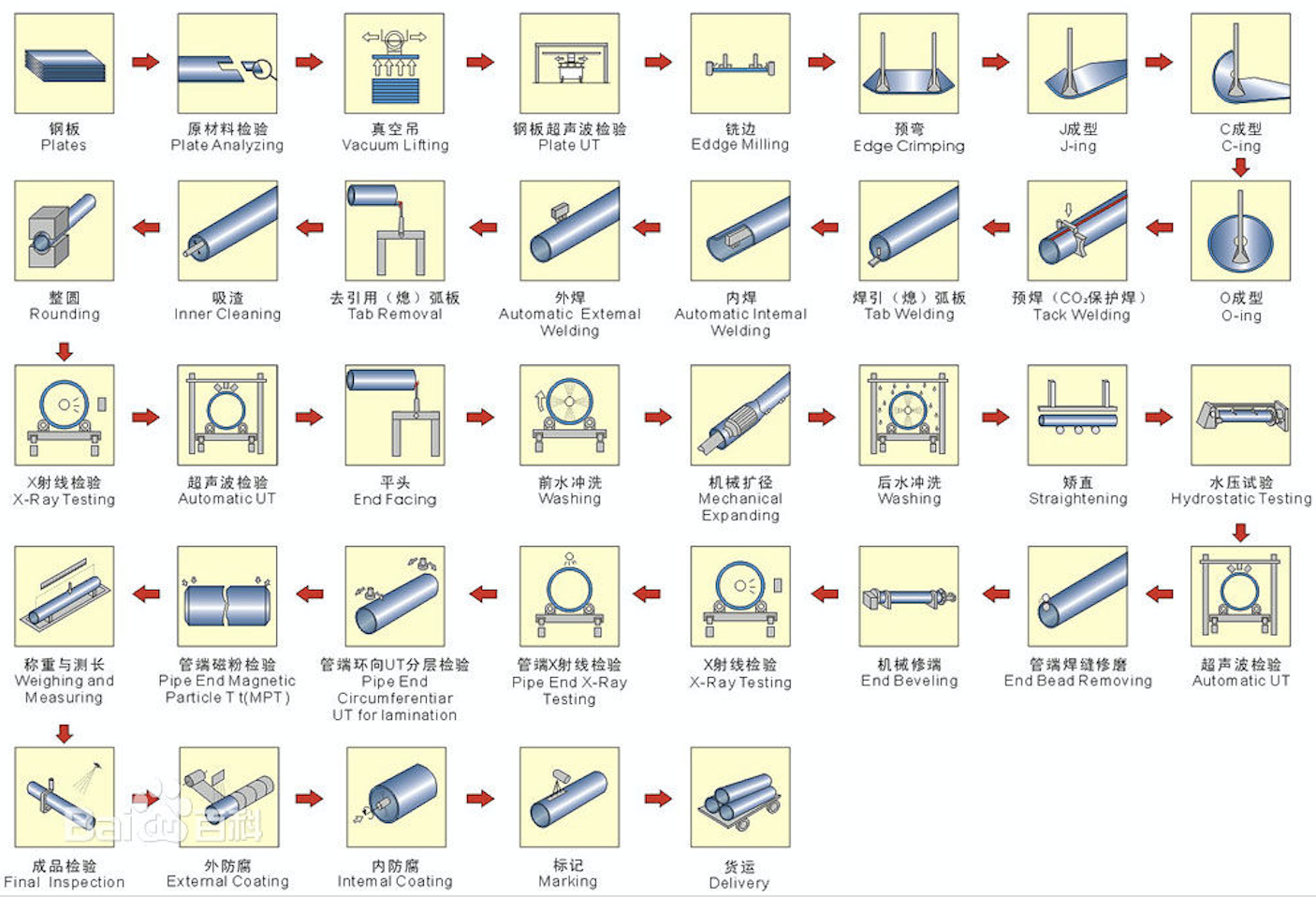

( 1.2 ) Longgitude Submerged Arc Welding Steel Pipe Production Process:

LSAW steel pipe main features:

A.The steel pipe has a longitudinal weld, and the inner and outer welds are welded by a submerged arc welding.

B. After the overall mechanical diameter expansion treatment, the internal stress of the steel pipe is small and uniformly distributed, which can effectively prevent stress corrosion cracking, high dimensional accuracy, and convenient field welding construction.

C. Adopting the precision welding process after pre-welding, the welding process is stable and the quality of the weld is high.

D. Welds are easy to realize non-destructive inspection during production and non-destructive inspection in the field during use.

E. The range of product specifications is large, and it can produce both small diameter and large wall thickness pipes as well as large diameter and large wall thickness pipes.

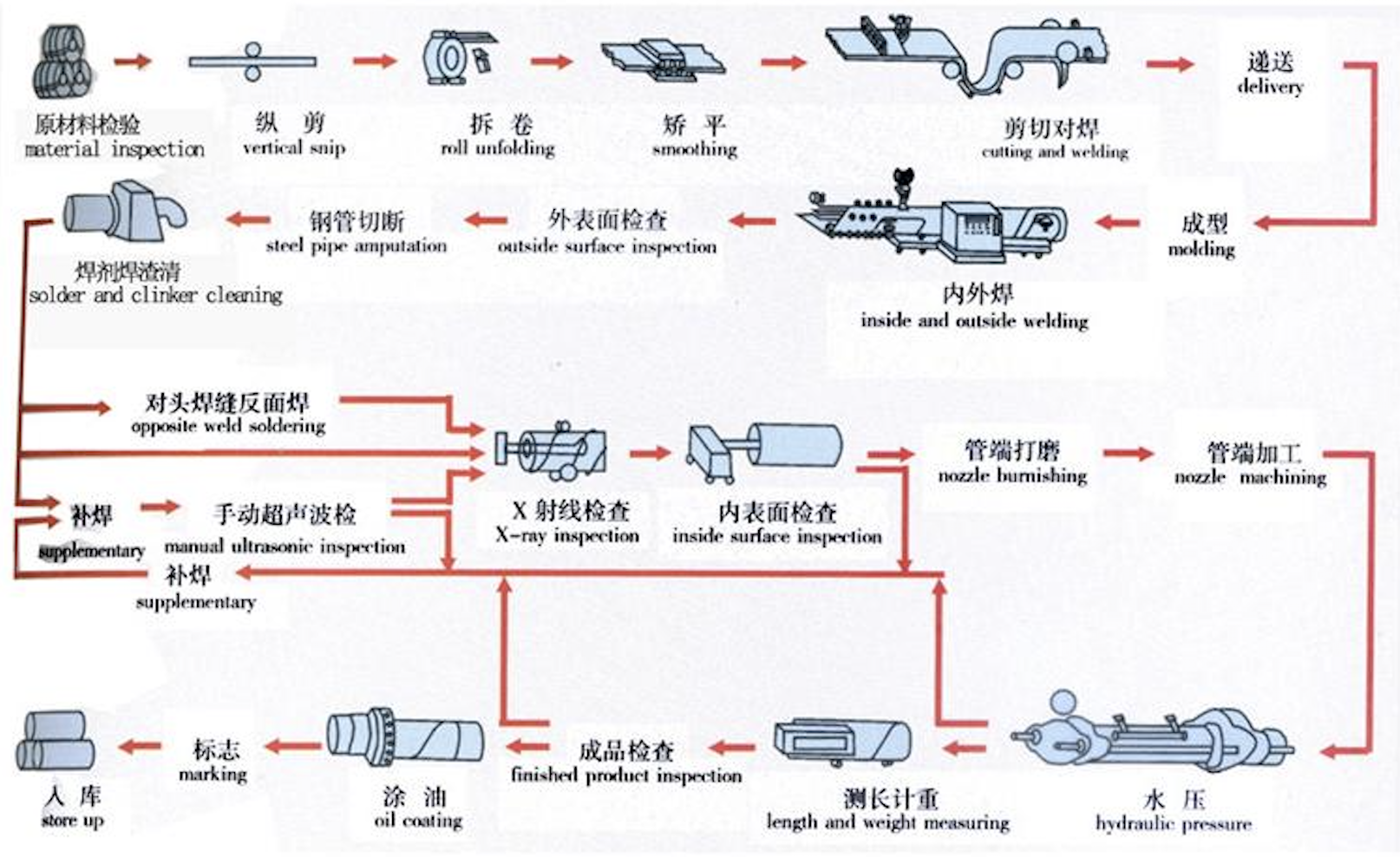

(2)Spiral Welded Steel Pipe Production Process:

Spiral steel pipe is made of strip steel coil as raw material, and is often extruded at regular temperature. It is welded by automatic double wire double-sided submerged arc welding process. Spiral submerged arc welding is an important welding method, which has the advantages of stable welding quality, high welding productivity, no arcing and little smoke. Spiral steel pipe is mainly used in water engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, and urban construction. It is one of the twenty key products developed in China.