Product Category

CONTACT US

Tel :

+86 18670012374E-mail :

sales@xiangjiasteel.com

Description

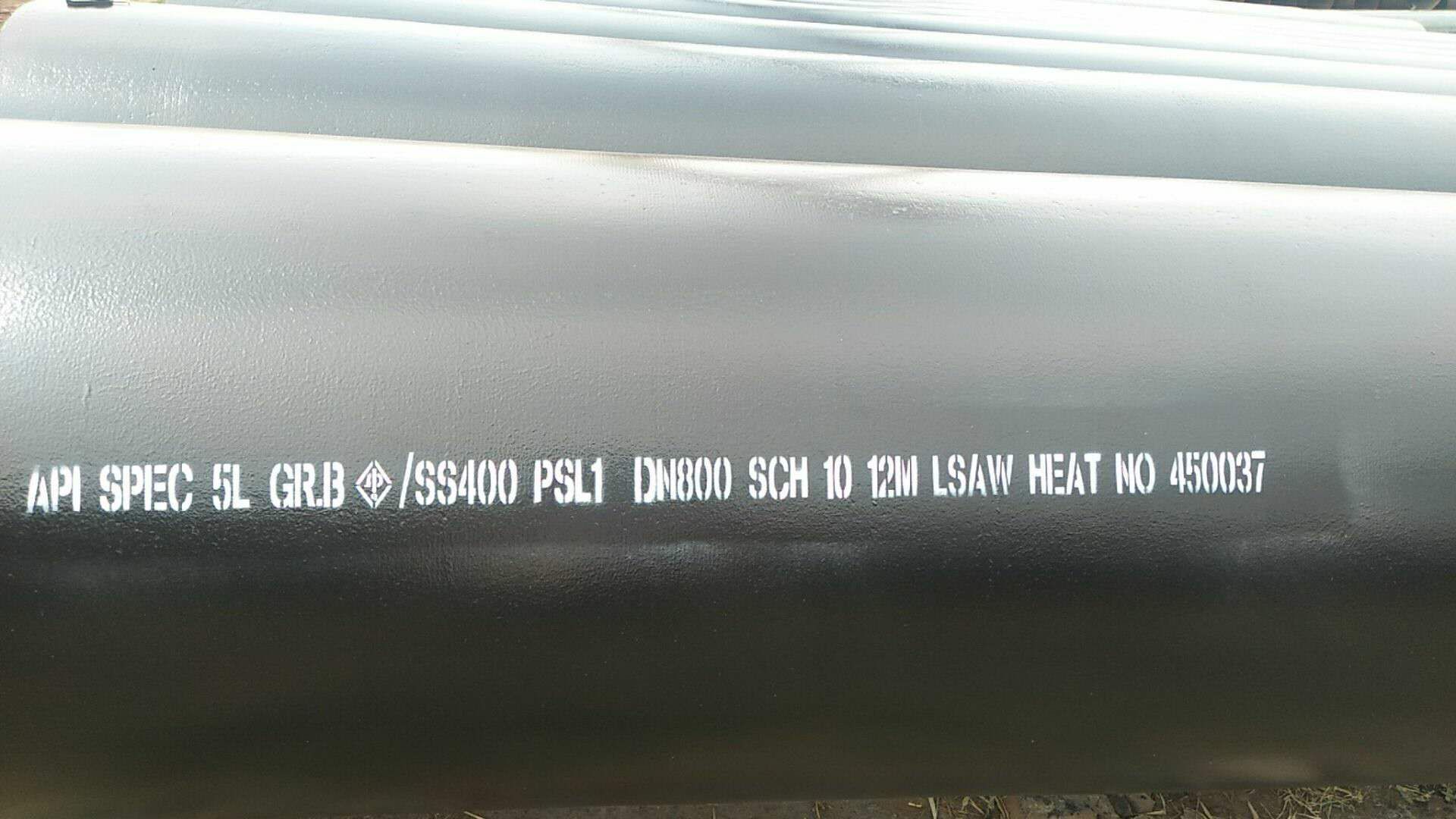

LSAW steel pipe is referred to longitudinal submerged arc welded steel pipe which is made of hot rolled steel plate or coils.

Grades:

For pipeline: API 5L GR.B, X42, X45, X50, X60, X60, X65, X70, X80

For piles: ASTM A252

Sizes:

O.D. | W.T. | Length(m) | |||||||

|---|---|---|---|---|---|---|---|---|---|

Inch | mm | Min.Yield Strength(Mpa) | |||||||

Inch | mm | 245(B) | 290(X42) | 360(X52) | 415(X60) | 450(X65) | 485(X70) | 555(X80) | |

16 | 406 | 6.0-14.0 | 6.0-13.0 | 6.0-12.0 | 6.0-11.0 | 6.0-10.5 | 6.0-10.0 | 6.0-9.0 | 6.0-12.3 |

18 | 457 | 6.0-15.0 | 6.0-14.0 | 6.0-13.0 | 6.0-12.0 | 6.0-11.5 | 6.0-11.0 | 6.0-10.0 | 6.0-12.3 |

20 | 508 | 6.0-16.0 | 6.0-15.0 | 6.0-14.0 | 6.0-13.0 | 6.0-12.5 | 6.0-12.0 | 6.0-11.0 | 6.0-12.3 |

22 | 559 | 6.0-17.0 | 6.0-16.0 | 6.0-15.0 | 6.0-14.0 | 6.0-13.5 | 6.0-13.0 | 6.0-12.0 | 6.0-12.3 |

24 | 610 | 6.0-18.0 | 6.0-17.0 | 6.0-16.0 | 6.0-15.0 | 6.0-14.5 | 6.0-14.0 | 6.0-13.0 | 6.0-12.3 |

26 | 660 | 6.0-19.0 | 6.0-18.0 | 6.0-17.0 | 6.0-16.0 | 6.0-15.0 | 6.0-15.0 | 6.0-14.0 | 6.0-12.3 |

28 | 711 | 6.0-20.0 | 6.0-19.0 | 6.0-18.0 | 6.0-17.0 | 6.0-16.5 | 6.0-16.0 | 6.0-15.0 | 6.0-12.3 |

30 | 762 | 7.0-21.0 | 7.0-20.0 | 7.0-19.0 | 7.0-18.0 | 7.0-17.5 | 7.0-17.0 | 7.0-16.0 | 6.0-12.3 |

32 | 813 | 7.0-22.0 | 7.0-21.0 | 7.0-20.0 | 7.0-19.0 | 7.0-18.5 | 7.0-18.0 | 7.0-17.0 | 6.0-12.3 |

34 | 864 | 7.0-23.0 | 7.0-22.0 | 7.0-21.0 | 7.0-20.0 | 7.0-19.5 | 7.0-19.0 | 7.0-18.0 | 6.0-12.3 |

36 | 914 | 8.0-24.0 | 8.0-23.0 | 8.0-22.0 | 8.0-21.0 | 8.0-20.5 | 8.0-20.0 | 8.0-19.0 | 6.0-12.3 |

38 | 965 | 8.0-25.0 | 8.0-24.0 | 8.0-23.0 | 8.0-22.0 | 8.0-21.5 | 8.0-21.0 | 8.0-20.0 | 6.0-12.3 |

40 | 1016 | 8.0-26.0 | 8.0-25.0 | 8.0-24.0 | 8.0-23.0 | 8.0-22.5 | 8.0-22.0 | 8.0-21.0 | 6.0-12.3 |

42 | 1067 | 8.0-26.0 | 8.0-25.0 | 8.0-24.0 | 8.0-23.0 | 8.0-22.5 | 8.0-22.0 | 8.0-21.0 | 6.0-12.3 |

44 | 1118 | 9.0-27.0 | 9.0-26.0 | 9.0-24.5 | 9.0-23.5 | 9.0-22.8 | 9.0-22.0 | 9.0-21.0 | 6.0-12.3 |

46 | 1168 | 9.0-27.0 | 9.0-26.0 | 9.0-24.0 | 9.0-23.5 | 9.0-22.8 | 9.0-22.0 | 9.0-21.0 | 6.0-12.3 |

48 | 1219 | 9.0-28.0 | 9.0-27.0 | 9.0-25.4 | 9.0-24.0 | 9.0-23.5 | 9.0-23.0 | 9.0-22.0 | 6.0-12.3 |

52 | 1321 | 9.0-28.0 | 9.0-27.0 | 9.0-25.4 | 9.0-24.2 | 9.0-23.5 | 9.0-23.0 | 9.0-22.0 | 6.0-12.3 |

56 | 1422 | 10.0-29.0 | 10.0-28.0 | 10.0-26.0 | 10.0-24.5 | 10.0-23.8 | 10.0-23.0 | 10.0-22.0 | 6.0-12.3 |

60 | 1524 | 10.0-29.0 | 10.0-28.0 | 10.0-26.0 | 10.0-24.5 | 10.0-23.8 | 10.0-23.0 | 10.0-22.0 | 6.0-12.3 |

64 | 1626 | 10.0-30.0 | 10.0-29.0 | 10.0-27.0 | 10.0-25.4 | 10.0-24.8 | 10.0-24.0 | 10.0-23.0 | 6.0-12.3 |

68 | 1727 | 10.0-30.0 | 10.0-29.0 | 10.0-27.0 | 10.0-25.4 | 10.0-24.8 | 10.0-24.0 | 10.0-23.0 | 6.0-12.3 |

72 | 1829 | 10.0-30.0 | 10.0-29.0 | 10.0-27.0 | 10.0-25.4 | 10.0-24.8 | 10.0-24.0 | 10.0-23.0 | 6.0-12.3 |

Tolerance of Outside Diameter and Wall Thickness

Types | Standard | |||||

|---|---|---|---|---|---|---|

SY/T5040-2000 | SY/T5037-2000 | SY/T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 | |

Tube end OD deviation | ±0.5%D | ±0.5%D | -0.79mm~+2.38mm | <±0.1%T | <±0.1%T | ±1.6mm |

Wall thickness | ±10.0%T | D<508mm, ±12.5%T | -8%T~+19.5%T | <-12.5%T | -8%T~+19.5%T | 5.0mm<t<15.0mm, ±0.11="" <="" p="" style="padding: 0px; margin: 0px;"> |

D>508mm, ±10.0%T | T≥15.0mm, ±1.5mm | |||||

Chemical Composition and Mechanical Properties

Standard | Grade | Chemical Composition(max)% | Mechanical Properties(min) | |||||

|---|---|---|---|---|---|---|---|---|

C | Mn | Si | S | P | Yield Strength(Mpa) | Tensile Strength(Mpa) | ||

GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

BS En10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

DIN 17100 | ST37-2 | 0.2 | - | - | 0.050 | 0.050 | 225 | 340 |

ST44-2 | 0.21 | - | - | 0.050 | 0.050 | 265 | 410 | |

ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

JIS G3101 | SS400 | - | - | - | 0.050 | 0.050 | 235 | 400 |

SS490 | - | - | - | 0.050 | 0.050 | 275 | 490 | |

API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |